About Us

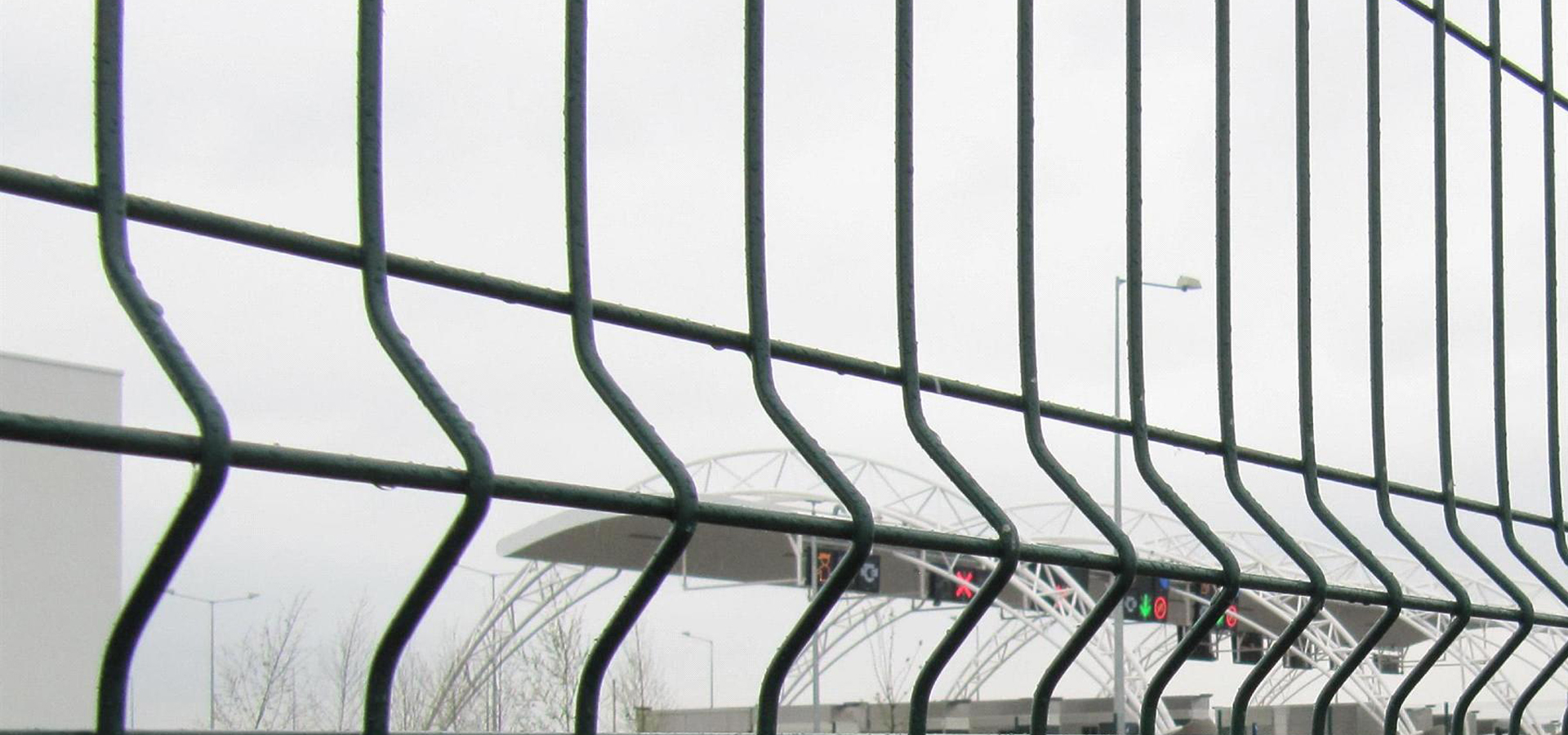

Hebei Loni Chiefence Metal Product Co. Ltd. has been in the steel fence business for 9 years. Our major products include welded mesh fence,, high-security welded mesh fence, 358 welded mesh fence, anti climb fence, chain link fence, palisade fence, Clearview fence,Roll top fence, double wire fence, gabion mesh panel, airport fence, BRC fence, euro fence, concertina razor wire, barbed wire. They are widely used in the border, temporary using, airport security, prison, construction project, such as security for highway, stadium, farm, and other fields for many countries around the world including South Africa, Brunei, Malaysia, Australia, New Zealand, South Africa, Nigeria, Mauritius, Russia, United States, etc. We have advanced equipment and a strict quality control process to promises high quality. At the same time, we communicate with customers on time and learn their needs timely to supply the professional and good after-sale service.

Read MoreF.A.QF

Q:Are you manufacturer?

A:Yes. Chiefence is welded mesh fence manufacturer.

Q:What types fence do you supply?

A:Chiefence can offer welded mesh fence,3D welded mesh fence,Nylofor 3D fencing,high security fence,Anti-Climb Fence,Clearview fencing,358 mesh fencing, 3510 Mesh Fencing,Double wire mesh fence,twin wire fencing,BRC FENCE,Roll top fence,Galvanized Chain link fence, PVC coated chain link fence,Airport fence,Picket fence,Curved picket fence,Palisade fence,Temporary fence,Gabion,Hesco,Fence Gate,Concertina Razor wire,Flat drap Razor wire,Barbed wire,Corral Panels,Fence post adn Accessoies.

Q:How is the the quality?

A:Chiefence product welded mesh fence as per BS EN standard.

1. The wire is Q195 or Q235 materials

2. Tension strength is 350Mpa-900Mpa

2. Wire diameter and mesh size as per comtomers requriement.

3. Welding Strength is over 55% of the tension strength of fabric.

4. 7 Surface treatment options confirm the Anti-Rust Grade.

A. Electric Galvanized(8-12g/m²) + Polyester Powder Coated (All colors in Ral)

B. Electric Galvanized(8-12g/m²) + PVC Coated

C. Hot Dipped galvanized(40-60g/m²) + Polyester Powder Coated (All colors in Ral)

D. Hot Dipped galvanized(40-60g/m²) + PVC Coated

E. Hot Dipped Galvanized after welding (505g/m²)

F. Galfan(200g/m²) + Polyester Powder Coated (All colors in Ral)

G. Galfan(200g/m²) + PVC Coated

Q:Do you have clients in my country?

A: Chiefence produce and export welded mesh fence to South Africa, Brunei, Malaysia, Australia, New Zealand, South Africa, Nigeria, Mauritius, Russia, Mozambique,United States, etc

Q: What is the production progress of welded wire mesh fence panels, BRC fence,358 security fencing, Clearvu fencing, galvanized anti-climb fencing?

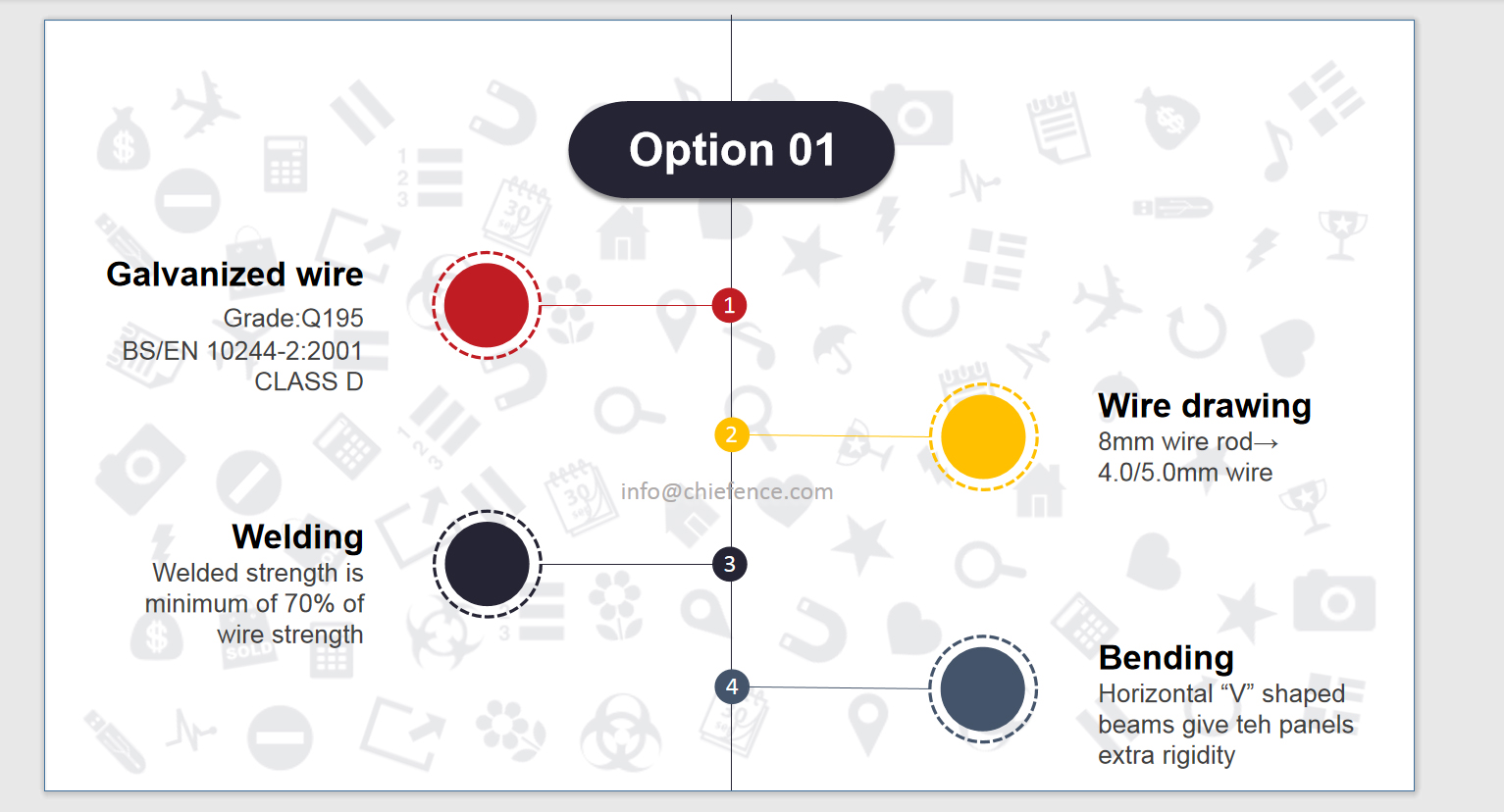

A: Option 01:Galvanized +Powder coating

Step 01: We choose Grade Q195 wire, Galvanization standard as per BS/EN 10244-2:2001 Class D

Step 02: Straightening iron wire. This is important step to keep the fence keep strainght.

Step 03: High quality welding means higher cost and poor efficiency. But we still keep High quality wire strength welding.70% of wire strength.

Step 04: Bending. Professional bends can make the panels rigid.

Note:After about 4 steps,welded wire mesh fence panels, BRC fence,358 security fencing, Clearvu fencing, galvanized anti-climb fencing have good physical property. It is hard,straight,rigid,strong.

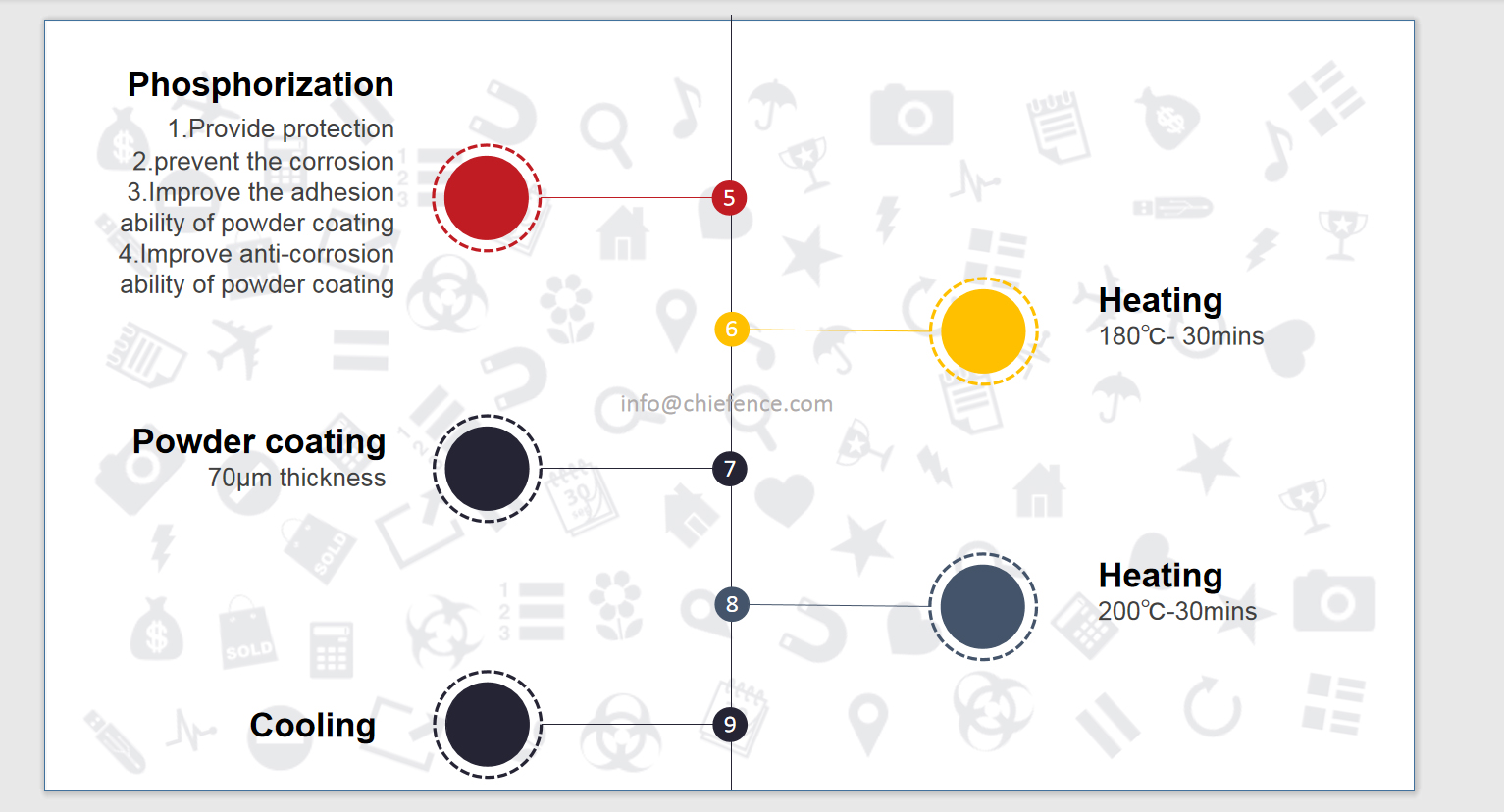

Step 05: Phosphorization. This is a very important step for Anti rust quality.1st, The Phosphorization film can provide protection.2nd,The Phosphorization film on welded wire mesh fence panels can prevent the corrosion,3rd The Phosphorization film canimprove the adhesion ability of powder coating.4th,The Phosphorization film can improve anti-Corrosion ability of powder coating.

Step 06: 180℃ - 30mins Heating

Step 07: 70μm-100μm Powder is coated on welded wire mesh fence panels.

Step 08: 200℃ - 30mins Heating